In this digital day and age, it has become easy to gain access to data to help inform your business decisions. Yet, in the agriculture industry, leveraging digital tools can often be seen as a little bit unconventional. Taking the leap of faith, Kurt Lambright, an Indiana farmer, started his journey with the digital process through the help of AgriGold Digital Ag Field Specialist Jason Carey. Together, they join Todd Steinacher in this episode to share how they worked together to help Kurt in fully adopting digital ag. From yield maps to software and equipment, Kurt and Jason take us through it, guiding us to efficient ways to utilize our products, make higher yield, and put more on the bottom line. Follow along to this conversation as you learn how to take advantage of the digital tools and platforms out there, ultimately changing the game for your farm.

—

Listen to the podcast here

A Leap Of Faith: One Grower’s Journey Into Fully Adopting Digital Ag With Jason Carey And Kurt Lambright

In a past episode with Jason Carey and I talked about the digital journey. I’d like to introduce my guest Kurt Lambright, an Indiana farmer, and someone who has begun his journey with the digital process. Kurt, I’d like to welcome you to the show. At the same time, I’d like to welcome Jason back to the show since he’s been very involved with you during your digital journey. Welcome to the show, guys.

Thanks, Todd. It’s great to be here. Thank you to Jason for the work that he’s done with us to help us on our journey. We look forward to sharing a few insights of what not to do and a few that we’ve had some good things happen.

Todd, thanks for having me back. Kurt, thanks for taking some time to work with us on the show and give a little bit of your perspective that will be invaluable for us and the growers.

Before we dive into the episode, Kurt, if you would, give us a little background about yourself, your family, and your operation.

We are located in Shipshewana, Indiana. The farm is KC Squared Farms, LLC. A little background behind that. I was born and raised on the home farm here. I graduated from Purdue. My father would be considered a second-generation farmer but the story goes a little deeper. My grandfather was here. He got some health issues and lost the love and desire to be out in the tractor every day. He had sold the farm and then somebody had signed a purchase contract. They had some workings together. He sold the business in 2015 and I graduated from Purdue in ‘15. Now, we’re working our way. It consists of my parents, Kevin and Carrie Lambright, and my beautiful wife, Paige, that I’m married from my hometown. She’s a great warrior in keeping the family and the dream alive. We have a little daughter, Piper, and another one come the middle of the planting season. We like to keep things interesting. That’s where we’re at.

That’s an amazing story that the spirit of farming lived on through multiple generations. Your path maybe took you to a different direction but ultimately, it led you back to the home farm and allowing the opportunity to do what you love. In the past several years, you’ve embarked on a digital journey to hit higher yields. What are some of your paths that you took to hit higher yields?

To give a little bit more background that would tie us into that point of view is when my father was at the family business, he had custom hired everything. In my summers from college and high school, I had worked for a couple of other farmers. I gained some knowledge while we were custom hiring our own ground. I came back after I graduated and worked for the guys that were custom hiring. I never was able to create my own digital journey per se but I definitely was introduced to it and could start seeing the fists and what we’d like and what I thought might work for us. That’s where we started. It’s been a journey in itself, and we continue to dive into the journey.

As you’re embarking in your farming operation looking at new technologies, where do you gain knowledge and find these new ideas from?

A lot of it is developed. We’re big believers in anything. We believe relationship is where things start with. Number one, our relationship with our father our God is important to us, but then anything in life can be developed into a relationship. That’s where we look for a lot of our knowledge. That’s where Jason, Tyler Bouse, now Josh, AgriGold as a whole comes into play. We look to our suppliers and people that are more intelligent than we are in each perspective. Sam Younglove has been a great asset with us from our local dealership, John Deere of GreenMark.

He’s invaluable when it comes to finding the right hardware-software. That’s where we worked with Jason, our agronomists, and different people that help us find and utilize that equipment to reach our higher yields, look into things a little deeper, doing more variable rate, applications whether it be seeding, fertilizing, soil testing, and the whole gamut. We’re trying not to hit a home run on everything. We’re trying to have a pretty good batting average on each facet. If we can get an increase from doing one thing or the other, 2 or 3 bushels that eventually add up and we like to improve on that.

That’s a great tie-in to our last episode, for sure. We talked about the importance of the relationships with your different dealers, especially your equipment dealer. We were talking about the hardware and equipment that it takes to get started in this space. Sam has done a good job of having a good relationship and a good asset at his John Deere dealership to purchase this equipment, acquire it, but doing it in a way that works for him, his father, and their operation. He’s got that set up ready to go. That made it easy for us at myself, Tyler Bouse, and Joshua Alderman. There are two sales reps to come in and make everything that we offer work. We’re going to offer recommendation on. What we’re passionate about, the seed, and the performance of that product and make it go from there. I want to point that out. That’s a good tie in back to one of the main points we pointed out.

I liked the fact that you do value the relationships with your suppliers. In the crazy era farming now, sometimes relationships aren’t as strong and it’s hard to develop some of these relationships. I can remember a couple of years ago working with a grower and trying to upload a VR script in their planter. We worked on it for a long time and we eventually gave up on it honestly so they could go to the field. Later we find out, the software within the planning system wasn’t unlocked yet and that grower had not had a strong relationship or communication. They did with the equipment supplier but not with their digital specialists within that organization. It’s so important you find out who all your suppliers are and who all the tech guys within those organizations to make sure your systems are set up for it. When you do bring in a VR rep for your planning, whatever hybrid a variety you’re working with that you’re ready to go. I very much commend you for being proactive in establishing and cultivating those relationships.

Todd, I liked how you brought that into the topic for what you had to say there. I have one story that I love to tell about our first journey and it includes Jason. Through our equipment dealer and technology that we decided to invest in, we do have all green tractors, we’re linked up with JDLink, and connect. My father, as I said, farmed earlier, got away from it, had no idea what technology was in farming. He was used to 276’s international for bottom plow and he planted, and that’s what he did.

Now, it’s a whole new ball game and he was going to plant beans. We’d sat down with Jason and Josh to put some recs together for variable rate soybeans. We’re going do two fields to do some tests and trials. I’m planting corn in different fields. Jason is doing his thing wherever he’s at. I get a call from my father and he says, “What is going on?” I said, “I am not sure, dad. Let me see.” I got into a monitor and was able to see what was happening. I thought, “I don’t think Jason would make a mistake but we’re all human.”

Long story short, we wanted to do a low pop test strip and we wanted it to be 100,000. We missed one zero. It dropped to 10,000 and the planter shut off. Dad, not being the most technologically advanced, says, “What do I do?” I said, “Let me make a call.” I called Jason. Jason sends that new prescription in, he was planting, and we were moving. That was the relationship where if it was on our own, it wouldn’t have worked that way. Something would have we scrapped it and said we’re planning to stray population. Here, we were able to call Jason within minutes. It was uploaded and he was back running. There is an efficiency standpoint of that relationship with your people that is worth investing in. You’ve got to look more than just the dollar.

What I like about that is not only having those relationships with industry folks but even with on the own farm. I can remember a couple of years ago, I had a client who was doing a VR, they’re in an area planting and the whole system shut down. Long story short, by the time the field was established the boundaries, the rack was built, somebody else within the operation brought a dozer in, knocked out a bunch of trees, and made the field bigger. Whoever was planting were still in the field but the monitor itself says, “We’re out of the field. We’re shutting down.” It took so long to figure that out but you ask enough questions, you can figure out some of these issues and it’s asking the right questions. As you think about your digital journey, at the end of the day, what is your goal by having all this technology? There’s an investment to it. Not only financially, but there’s also a time investment.

Back from where we started, we custom hired most everything. It wasn’t until few years ago that we first bought our first piece of equipment that we would even feel able to take advantage of any digital technology perspective at all. We did dive in. We went head first and what we try to gain from it is we don’t want data. That’s one thing my father preached with some different businesses and stuff. You can have all kinds of data. We need to utilize the data. We didn’t want to have a yield map and say, “This is pretty.”

We want it to be able to go back, look at it, and use it. That’s somewhat where our journey took us to where we’re seed corn, commercial corn, and soybeans. Our seed corn is where most of our acres are. We can never use the yield map. We needed to find different avenues of different things to try on some commercial crops that we could then mirror into our seed corn production that would help us compete a little bit better against our competition. Our journey consists of not only starting out with yield maps, guidance, prescriptions, but it dives into literally down to the fine things that keeping the equipment that we invested in.

We’re using points to put where stones are. We have some giant boulders out in our fields. That has allowed us to go back with the skid loader, find exactly where it is, and not waste a bunch of time. That’s somewhat of our digital. We’ve run the whole gamut of profitability per field down to picking a stone in a field. That’s where our journey is. We’re invested in MixMate, which is a chemical solution to mixing. That’s going to even drive more data into knowing which load we produced into our sprayers. We’re not trying to run tons of data. We’re trying to utilize it to make a higher yield, see where we’re utilizing our products, our inputs, and nothing is getting cheaper. We’re trying to put it to the most productive acres and ultimately put more on our bottom line.

That’s a great point when you’re talking about your digital journey. Todd, as we’ve talked about, many people get started with this and they enjoy the aspect of yield maps or seeing live how things are performing on the planter in the combine. There’s an emotional connection to that but that’s not the whole story. That’s not where we make a lot of impact on an operation. You have to take it to that next level. As Kurt said, not have data but utilize it, see how you can benefit from it, and get better. We’ve done that a lot of ways whether it’s strip test or it’s testing out products like you’re talking about, utilizing the technology we have to focus on those areas, and see what we can learn to apply the next year.

Kurt, it seems like a yield map field monitor is in everybody’s combine. We use it very aggressively. It might be the basic fundamentals of every decision we make. As you look at a yield map, how do you pull data out of that to make recommendations or see insight on a given field? A couple of scenarios, maybe.

I’ll give one thing that we found out. 2020 crop season was the first year that we had our own data, our own combine, and everything. We were in control of that was one nice thing. We came in and we’re using MyJohnDeere. We’re able to use the Op Center instead of using Apex. We were thrown into something that was fairly new and fresh. We’re learning as it progresses and we’re not trying to get away from our old ways but one of the things that was very interesting is we did a prescription or a VR test on our one farm down South in here. Jason has set it up.

Everything was great. The only problem was KC Squared Farms struggled in getting their stuff together as our first year. It was commercial corn the year before irrigated and we planted it. That is literally what we did. We did not shop stocks, did not work it at all. We planted it, rowed and go sprayed it, and we had a crop. The fields did quite well for what we thought might happen. The problem is in 2019, when we harvested that corn, half of the field was west when we harvested it. I’ll say that to say the least.

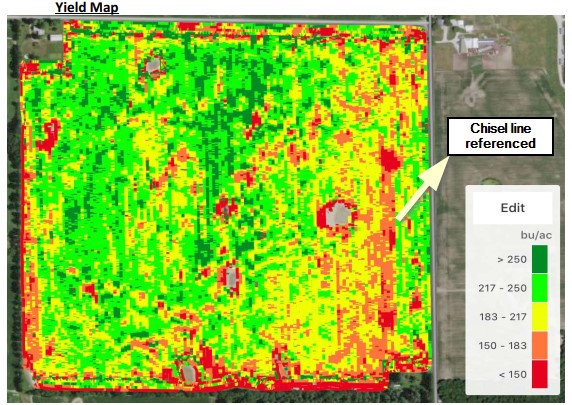

It shouldn’t have been on there. Fast forward again, 2020 yield map, there was a strip while we’re sitting down, going over the actual VR strips, not even in the VR that something didn’t quite seem right. I had our one guy go down and do a little bit of tillage chiseling on some dry spot or on some washouts and wet holding areas that had dried up the stream. I told him, “Let’s do a little bit along the road. I knew that was pretty heavy dirt.” Come to find out, we’ve looked, we thought it would but we could have chiseled it 3 or 4 times and still made money off of it.

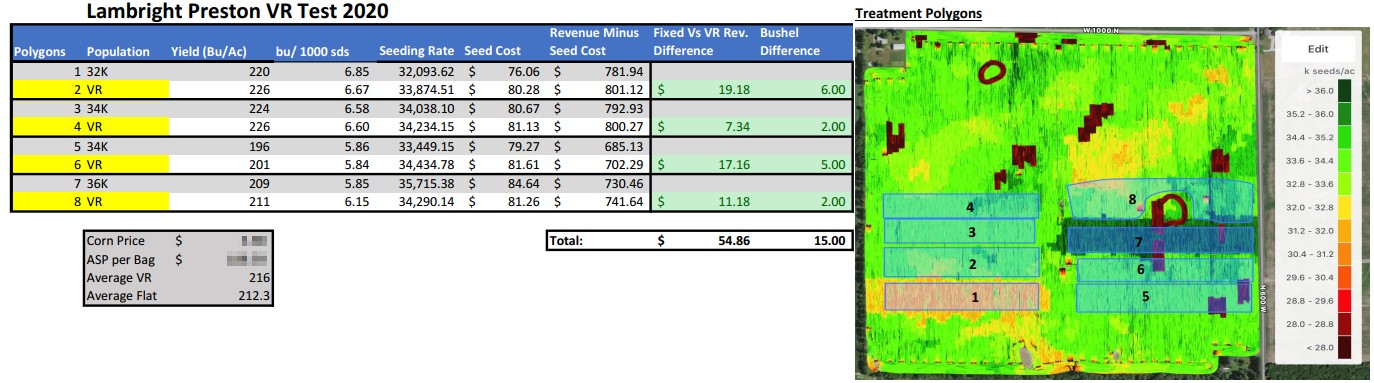

There was a good solid line that you could tell the difference that we were 30 plus bushel different from where we chiseled and where we didn’t. That wasn’t across the whole field because some of the ground was a little different and we weren’t on it quite as heavy. That’s one thing that we did look back on and say, “It might have taken a little extra time.” We want to get a little more into no-till but we need to have a better gauge of what we’re doing. This yield map showed that was where we needed to do. That’s one scenario. The second scenario is back to that same field, Jason now is able to sit down with us and say, “This is what it paid and what it did.”

Could we figure some of that out yet? That’s where I go back to relationships. Don’t take advantage of the guys but that’s what they’re there for and that’s what they specialize in. Talk to them. If you have a great one like we do, it helps the whole scenario that you’re not trying to pull everything out. As long as you have good dad and are willing to work with them, they’ll usually work with you. We’re looking forward. We’re going to do some VR rec on nitrogen, some side dress, we’ve got wide drops, and we’re going to do a few different things there. We were looking at them for a general sense. Our first year with our own good solid data. Not saying that we didn’t have any good stuff before but now we know exactly where it came from and what it is. That’s where we’re at.

As you make your zones, whether it be from a nitrogen standpoint or your VR recs, how do you go about designing your zones? Are you looking from a grid standpoint, organic matter, or overall productivity-based off yield maps? What’s the process you go through for that?

We do start out with a 2.5-acre grid sampling. That comes from our agronomist. We even have another supplier that Jason doesn’t even know about that is looking at some of our problems fields that we’ve had a manganese efficiency or yellow corn strips. We kept on feeding it manganese. We’re trying to dive into figuring out exactly what that needs. We’re taking that and applying that to some different people’s programs per se, in their spreadsheets or what they’re testing and running. We’re starting from the bottom and starting with our fertilizer recs. Let’s try this product on here. Let’s do some strips of this. That’s where the whole journey comes into play. In my mind, now we have the capability of knowing exactly where that strip of the different product was applied, where we’re trying something a little heavier, and then we’re taking that into our VR rec. That’s where I got it and met Jason and using the topography, the functional soil samples, and tying everything together to give us a very good recs on what we should be putting out there.

In my years working with growers digitally or as an agronomist trying to improve yields, so often we think that to get higher yields on an average, it’s going to be we’re going to take our best area and make it great. In reality, if we want to raise our averages, it’s not improving the best areas to make them great. It’s more finding the poor areas and making them average, finding the average and making them better and making them good. To me, by having all these insights on yield maps and organic matter, your basic fertility, and your 2.5- acre grids, amongst other things you’re doing, that’s how we’re going to get higher yields across the board and improve profitability. Correct me if I’m wrong, Kurt, but for many years, we farmed 180-acre field. Now, it’s time to farm 81-acre fields to improve these things. We have the technology and we understand the agronomy to it. Now, it’s time to put them together and make good decisions.

I agree with that wholeheartedly. This is not a dig at our custom operations at all because they did use variable rate. Anything in life, when you have complete control, you can help make that better or do it how you want. We were able to utilize. That was our thought process. Exactly what you said, Todd, on the 81-acre fields. When we bought a Planter, we bought ExactEmerge. Did we need an ExactEmerge? No, we don’t run across that many acres but my dad and I, number one, are trying to do most of it ourselves to the efficiency standpoint, and number two, being able to get down per grow of populations and even fertilizer.

It’s amazing the difference that we’ve seen in year one. We look forward to that and the future here as well. I will say one thing that another field or another example that ties what you said about each individual, bringing your poor fields up is back on our muck. We have sandy muck, sandy soil, black muck, or black sand, whatever you want to name it, it’s not good dirt. We’ve had some seed leftover from the year before and on the 72-acres, I think it was, we had put three different hybrids out there. We came back and luckily, we put three different varieties in the same field to see and use up some of the seeds that we had. It was close to home.

We’ve got 100-day that we wanted to try out. We put it out there, we came back to spray it, and I was sick. I called Tyler. We were still dealing with him and I said, “Why did you let it pull onto the seed? This is not good, the sand.” I never did get a great stand count because I was too miserable to even look at it but it came out to be in twenty. That would be a high number. It was more in that 17, 18 range. Fast forward to harvest, we get out there, and it’s one of the first fields we start on. There’s a difference in yield.

I’m not going to say that we had a one dry, you got 224, one goes 230, and one goes 181. The 181 was with low population but also have the dry corners. There might be a map on the blog or something that you guys could see if they want to look but it’s 103-day or 100 days of what it was, it completely amazed us and gave us a definition of what your flex is because these years on the 19,000 that was out there were monsters. We would have been happy with 125-bushel corn out there and we had 181 bushels.

That helps give us an idea. Without the digital journey, we wouldn’t have realized what number that was and what worked. That gives us a future that on some of this ground, we might not need to be pushing the population quite as high. We can use a greater variety that would adapt to that soil a little better. It gives us an idea too with our different varieties and different tests that we can tell for the future to hopefully improve those lower producing acres.

For so long, from a seed standpoint, specifically corn, we always categorize things as offensive-defensive. It can’t handle wet feet. To me, those are very broad theories or placements to pigeonhole the given field. There are all these transitions within a field. Instead of be in 180-acre field, we have 81-acre fields. You might have all three of those situations in a given field. As we look at modern hybrids or the hybrids that are advancing through breeding programs where they’re very looking much at high yields but it seems like there’s always a chink in the armor. Whether a wet feet situation, does it like a particular stress, or favors late season nitrogen.

What you’re doing, by understanding things, to the 2.5-acre grids, fertility, and you’re understanding topography and drainage, the more you know about your fields, when you are talking with your seed advisors, your agronomic support, you have a better idea of which products work for you and where you can place them. I’ve seen time and time again where we take the best hybrid and we put it into the worst situations, textbook where it does not need to go, and it’s almost a train wreck. We can almost take an average product, I don’t want to say soup up the agronomics to it, put it in the best of the best, and all these other places. We can get a little bit higher yields there.

From my standpoint, I like to know as much as I can on a given farm and field but a lot of times I don’t always know those insights. You have a wealth of knowledge of all your fields and where things need to be placed. When you do meet with your seed advisors, it’s not, “I need an offensive-defensive hybrids. Here’s a given hybrid. Here are some of the challenges that we need to manage around it.” You in your mind know exactly where it needs to go or exactly where it does not need to go. How does having all this technology help you either better select your hybrids or better place your hybrids?

We’re going to go back to my relationships theory and that’s where Josh Logman came into play. Definitely, Tyler in the past. Farther down the road or past, my father looked was uptown in business. He wrote a check to Pioneer and nothing against the dealer. We still do business with some great friends. They did the best they could but we didn’t give them any information. Now we have the information and that’s what has made was a simpler time for us to choose varieties because we sat down with Josh and said, “Here’s where our fields are. This is what we’re looking to do next year. We know this is a problem area. This ground very drowsy. This ground has proponents of being wet.”

The information that we gained from all of our journey and data that we’ve collected helps us utilize what we’ve received and know that is ground proved. We can utilize that to say, “This variety is going to work and this variety isn’t going to work.” We haven’t got into the dual hybrid technology yet. As I said, we’re mostly seed corn. The commercial is definitely we want to make every acre count but we haven’t been able to utilize that quite as much as we want to, but maybe in the future. That is something that our hybrid selection in the last several years has definitely increased our yields by far. That’s simply because we knew what we were dealing with. That’s our journey.

I hope it improves and continues to be a journey. I don’t want to be a dead end. We were out in Colorado with my sister and we didn’t hike Pikes Peak but I thought about that as far as we want to get up here to this average, say we have a ballpark. It’s always good to have goals in life. Say we want to get into a 250 bushel average across the farm. That’s great but I’m not going to be able to from one year hike Pikes Peak. I need to take a journey, utilize different resources, train to get there finally, and maybe we’ll step up to Mount Everest. I don’t know. It is a stepping stone in the journey that we need to utilize each and everything that we have at our fingertips to make it work.

To tack on this situation, I met with three of our multi-hybrid cooperators. I’m talking about that multi-hybrid planter. I’ve got a soapbox and I’ve been starting out not even liking the offensive and defensive terms anymore and trying to get away from those because what it comes down to is the piece of soil that we’re looking at offensive or defensive and those characteristics can change for every farm you go to. I’ve got a multi-hybrid grower that considers a farm offensive or defensive based on emergence and another one is based off the typical yield and drought tolerance but then you can go to somebody else who’s surrounded by a lot of woodland ground that is looking at, “Can I get a plane in there to apply fungicide?”

They select defensive of fungicide tolerance. That also goes back to the breeding program and our hybrids, they become more adaptable to a lot of different acres, which is where I’ve been so proud of hurt in this journey now that like you said, they don’t have a multi-hybrid planter but they’re still selecting hybrids the best they can for those 81-acre fields. Now that they’ve got the equipment and they’ve got the data gathered, they’re able to do that and start to break down and overlay planting maps, overlay tests they did with different products. We might be testing those out because with that information, you can start to dive in and see, “Is that part of our field considered offensive according to the characteristics we want to pay the most attention to, or is it considered defensive?” That was my soapbox in that topic you guys are getting into.

I’ve come to realize it’s important for everybody involved on the acre. The farmer, people that’s in operation, and suppliers by being on the same page of what are challenges to the given farm. As you said, one might consider it a challenge based off emergence or from an operational standpoint. I would almost challenge anybody reading out there, get a piece of paper, get a spreadsheet, whatever you want to do, start listing out all your farms and fields. Honestly, writing down 2 or 3 strengths of that field. We know we need to leverage to those strengths. At the same time, write down 3 or 4 weaknesses. Whatever you see as a weakness or a threat to that field.

Have those conversations with your suppliers and try to figure out, how do we take advantage of these strengths and maximize yield, profitability, labor, and efficiencies but also, “Here are the weaknesses of this farm. I can’t get a plane into it and apply fungicide on it. I need to make sure I’ve got a very healthy hybrid in there. I know there’s a drainage issue, so we need to make sure we’re not putting hybrid out there that doesn’t handle wet feet. The fact that there are nitrogen issues with a particular field and we know a particular hybrid wants a lot of nitrogen late in season to fill out the grain fill.”

If everybody in a management group within your relationships of your industry partners, you’re on the same team. The goal is to maximize your guys’ operation. Go and figure out these 3 or 4 strengths and weaknesses of every farm and start using yield maps, start using soul samples, digital imaging, anything at your disposal and start answering these questions. That’ll drive us to a point where we’re improving yields in those poor and average areas but also helping out to stimulate those great areas.

One thing to that, Todd, I appreciate exactly what you said. That is very good insight and very good information. I would love to piggyback on that but the one thing that I also want to say to all the guys out there that maybe are thinking, “Look at the expense. Look at the investment that it takes.” There is definitely an investment. I haven’t found anything being a farmer that’s cheap. Everything is always way too overpriced even your seed. Even though I love it’s overpriced but that’s the farmer’s common nature.

What I will say to those guys is it is worth taking a risk. Our whole journey started before we even had anything to do with hybrids, which it indirectly did. My father and I invested in a base station for our valley pivots were 90% underwater irrigation. It was a huge expense and it still does have some expense to it but we took a leap of faith and now we pay twice for what we did pay for it. It has been invaluable in helping us. We can start our pivots on wherever we’re at in the world. As long as we have cell service, we can start a pivot.

We also know when stuff goes down. When that hybrid needing water, we are on it and can know. Not just the technology or digital side of things that is directly unrelated to variable-rate recommendations or any of that per se but something that we’ve utilized and took a risk and seeing the reward. That’s what started us into this path of thinking, “Not always you got to take the investment side and the dollars into perspective. You can’t go out and leverage yourself way too far out there but it is value of looking at everything.” Even if you think, “Our farm can’t handle this.” Maybe it can’t right now but don’t ever say, “This is way out of our running and look at it.” Take a risk and chance. You might be happy with what you find out.

There’s a lot of tools out there. Software-hardware from a digital standpoint. It seems like the market is almost flooded with so many options out there. What I’ve always advised growers is go talk to somebody who’s not involved in the situation. Get their insight on it. You can be biased. I’ve had customers in the past that they go buy a lot of technologies, throw it on something, they’re in the middle of planting, and they call me and says, “Todd, why did I buy this?” I said, “You should have this conversation before you bought it.” There are a lot of technologies out there. They all do serve a purpose. Does that purpose align with your operation? That’s where it goes back to having conversations with these parties whether it’s the person selling the equipment. Talk to your seed folks or your ag retailers. They’re always working with different farmers, connecting, and seeing how things work. Start asking good questions and it’ll take you down a path where you want to go.

I would take you back on that and show my hand. We did something that we did not like and it cost us money and we’re still in it. We have a contract with a service provider that we thought was going to help our operation. There is some benefit to it, but we did fail. I’m not putting it solely on the product. I don’t think we gave it the time of day and the energy that is needed, but it also wasn’t a fit. The problem is we listened to a spiel by the salesmen, jumped on board, and never talked to anybody. I echo your statement, Todd.

Talk to people or talk to other farmers. We are annoyed the area farmers because we’re too dumb. We ask questions and it’s great. The knowledge that you can get from different guys out there that have used it. That’s one of the nice things about having some older farmers in the area that you can say, “This is where we’re at. Would it fit our operation? You know our operation a little bit. You guys seem to use it and love it. Do you think it could even be of value?” They can either say, “Yes, it is. No. You guys aren’t to that point or we haven’t seen the value last.”

I would agree. Ask questions. One thing that we argue, John, and it’s been a kick with dad and myself is watching YouTube. Sometimes it seems dumb but there is so much information out there that you can learn to change a toilet in your house to what this program does with an ag software. It’s amazing the knowledge, the comments, and the questions that even start your thought process to, “I should look into this. That’s a great idea but I’m not going to move on with it.” Look at the magazines. I like to look at pictures but read some things and gather some knowledge.

YouTube has been an invaluable resource for us even then to provide the step of asking your retailer, asking your agronomist, or talking with ag who was golden and find out, “I saw this product. What is this? Can you give us a little more information?” I say be open. Sometimes, us, as farmers, myself included, can be fairly stubborn and we’re going to do it our way because that’s what we’ve done or we don’t want to be told what to do. One thing to help our yields has been being a little bit more open and honest with ourselves that there is a better farmer out there than us so why don’t you use that to your advantage and ask them what they’re doing instead of trying to be the proud farmer that wants to say, “I’ve got the greatest yield and this is me.”

I come back with one state and then we came into this world with nothing. I plan on leaving with nothing to my name, per se, as I go. I hope we can leave a lasting legacy to my family. I’m not saying spend every dollar out there. That’s not what I’m saying in that sentence. What I’m saying is, you’re not going to hurt anything by trying something different because at the end of the day, somebody is not going to know you for they spent so many dollars on technology or in that nature. Hopefully, they will know you as a good person and a good farmer.

I’ve always felt bad over the years being the guy that asked too many questions but I gained a lot of insight for it. I always challenge everybody, ask me questions. My salesmen even call me all the time. They’re like, “Todd, I hate to bother you. I got a question.” I’m like, “No. That’s what I’m here for.” Let’s share knowledge here and improve what we’re doing. I applaud you for being proactive in that category. Kurt, as we wind down this episode, I’ve got three questions for you. I want you to tell me the first thing that pops off your head and how things happen. Question number one. From a planting standpoint, how has digital ag helped you make better decisions?

Digital ag has been our planting. That is exactly what we are with the variable recommendation. I’m seeing that it’s been included. It’s made our per acre profits, net, whatever you want to say, increase in one year. We can say that very truthfully, very honestly. There’s going to be a few acres that may be bottomed out, but having the ability to do it has proven. The test strips to show it even the general sense. It made our operations a game-changer that allows us to take to the next step hopefully.

Question number two. How has your digital technology improved your in-crop or mid-season management decisions?

The digital technology in that perspective is we did use some satellite imagery. That has helped some but I’d say more importantly, working with our agronomists that are walking the fields on a daily basis or weekly basis, whatever it may be. It has allowed us to pinpoint things that they see out in the middle of fields so we can then use our technology and attack those spots. We also can look back and say, “This is what we applied. This is what we need to apply yet and how are we looking.” We use tissue samples that allow us to go and find different areas of, “Let’s push this crop. We’re sitting all right. Let’s put those inputs somewhere else to make those bumps that yield a little bit.” It made us better and well-rounded allowed us to utilize our resources and our dollars investment in areas that hopefully will create our greatest return.

Third and last one. How has digital technology improved harvest/post-harvest decisions?

As I stated earlier, we’re a little bit newer on it because we haven’t had a ton of digital yield maps or that information until 2021. We’ve had some before, we’re utilizing that some but that’s allowing us to now ground proof look back, utilize, and see what we’ve done all year long. If it was worth it, it paid, putting the bottom dollar of what we need to be looking at, where we need to be pushing things at, and also allows us to see where we’re at for marketing purposes too. Knowing where we’re at on a field-by-field basis.

Before we close out, do you guys have any last comments?

One last one that I didn’t touch on because he’ll be reading this sometime is my father. As I stated before, he was one that didn’t understand a thing of digital technology and farming. We bought an Apex in 2009 or somewhere to see if we could play with the data from our custom operators. It worked all right but he always wanted to find something. I want to push the guys out there that, you might say, “I’m 60-plus I’m on the last legs in farming.” Find somebody, reach out to somebody, maybe it’s another grandson or a son, and see what they have to say.

I’m not saying I’m the answer to it but it is amazing if you get the right people in place of Jason, Sam, Adam out at GreenMark, or any of these individuals that can help you utilize data. It is not quite as big of a mountain as some people might think. He learned it in the first year. He is not perfect. I don’t know perfect. I don’t think anybody knows a perfect even engineer sometimes but it’s amazing if you utilize the ability of having those relationships. It can make something great and you can use it to better your crop and better your operations as a whole.

For my wrap up, I got to applaud to Kurt and his father. They are people that live their life looking to seek wisdom, and seek understanding. That’s what they’ve done through this process. We’ve talked a lot about investment and one thing that we can’t leave out is this does take a time investment. It takes want to learn how to use these technologies and to learn how they can benefit your operation. Kurt and his father have done that. They’ve taken the time to learn, trial and error, and they’re starting to see those values of it. Sometimes, this process can be hard because the benefits are a little delayed. We’ve got to wait a growing season at least to see some of these things come to fruition but they’ve stuck with it. I got to applaud you for that.

I want to take you back and echo that back to you guys because everybody in AgriGold, this isn’t a sales show but I will say, we have had an invaluable experience with AgriGold like the service and the support. One thing I have to say about you guys is that it’s not another dealer, and you guys don’t have a channel where we’ve had some agronomists in the past that they also happen to sell seed. You guys sell seed, you know your seed, and you’re not trying to sell us anything else and the service that you provide us. You make that purchase that much easier because we know we’re going to be having the support to make that a successful season.

Thanks for the closing comments. Kurt, I would like to personally thank you for coming on and also for sharing your digital ag journey. Hopefully, that can inspire some other folks. Jason, l would like to thank you again for coming back on the show. Also, for all the support they provide farmers like Kurt and their digital ag journey. For everyone reading, it’s never too late to start your digital ag journey or even to advance your digital ag journey. I challenge all of you to read, listen, and ask great questions of how you can advance digital ag presence on your farm. With that, thank you.

Important Links:

- Jason Carey – Past episode

- MyJohnDeere

Love the show? Subscribe, rate, review, and share!

Join the Yield Masters Podcast Community today: